More safety

In recent years the topic of safety on the track has gained the attention and importance it necessarily deserves. There are many areas in which the need to protect, prevent, inform and manage a risk which, when not calculated, can be the cause of the worst outcome is clearly recognised. The racing world has always been seen as the center for the development of the best solutions, where research applied to competition allows the best performances to be achieved, constantly touching the limit of every element involved in performance. Alpine skiing demonstrates how many racing tools were born from a need for protection: think of helmets, gloves, back protectors or shin guards, all objects to which the laws of aerodynamics, physics and mechanics have been applied to be able to earn even a few cents without ever losing safety and reliability. In this panorama the limits are not always the same, making continuous updating essential, recognizing that the risks depend directly on this typical evolution of the physical and technological limit. So here and in this precise context, "personal impact protection devices" include "cut" ones. In detail, we know well how modern skiing has been able to stress every aspect related to performance, going so far as to treat the edges as real blades with cutting properties comparable to those of work tools dedicated to cutting and pure cutting. Sharpening and surface treatment processes which in the event of a fall once again increase the risk of injury with a dynamic already known and very similar to that of short track, hockey and long track skating. We are talking about very serious injuries with severe consequences.

Considerations

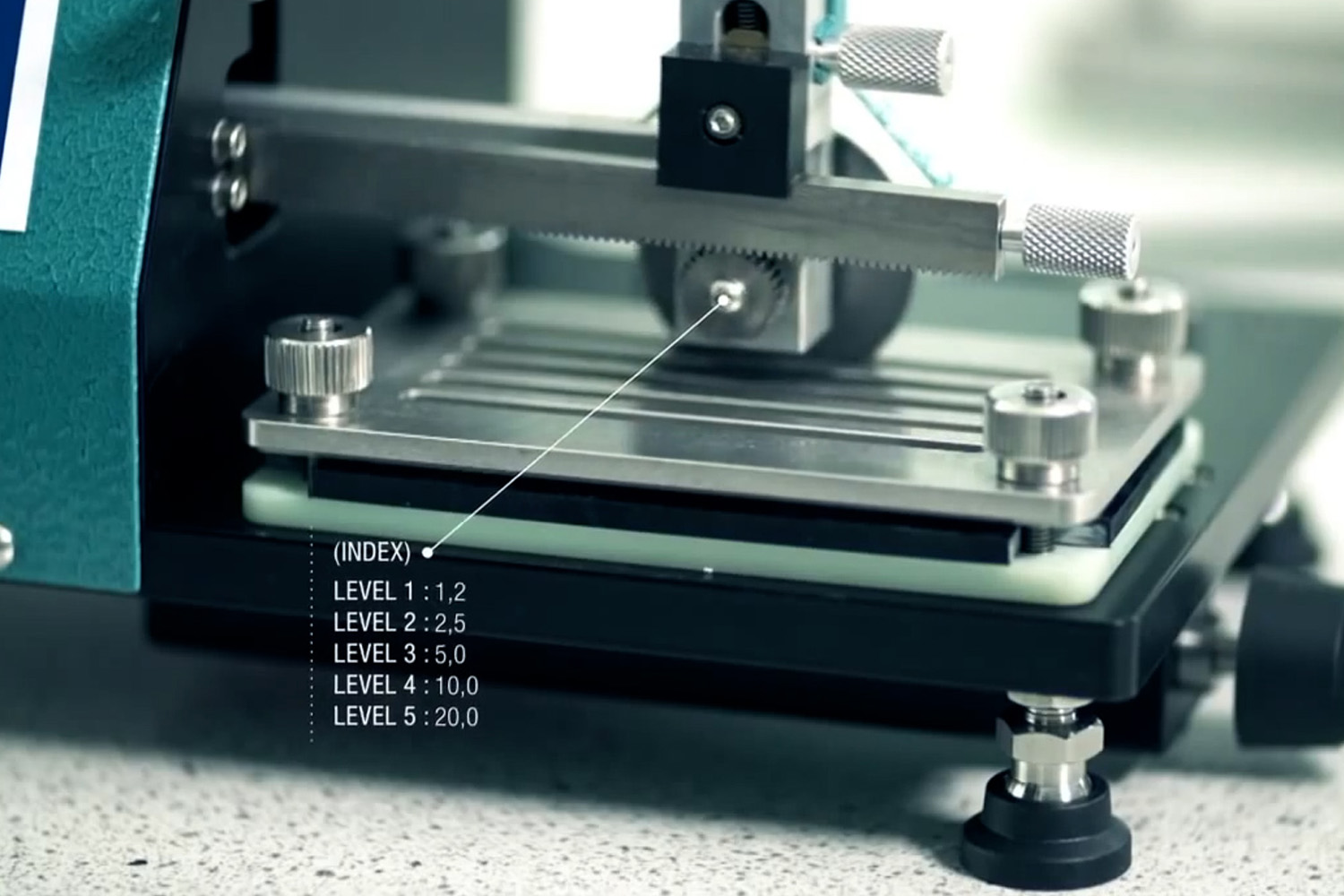

The personal cut protection devices that meet these needs must obviously be wearable, necessarily functional and necessarily effective. In most cases we are talking about fabrics. Fabrics used for the construction of garments dedicated to military and hospital activities, fabrics that give rise to safety covers in construction contexts and fabrics with many applications in the world of work. This is a sector well protected by international regulations with standards that are the basis of the manufacturing capabilities of every company involved in a production process of this kind. The European reference standards are: EN 13998, EN 1082-2, EN 388:2016, while the American ones are: ASTM D – 276/'87, ASTM F 1671, ASTM 1342, ASTM 2878. Without going into the specifics of each individual legislation, let's try to understand what the rules characterize a cut-resistant fabric. The test methodologies for an anti-cut fabric all involve the use of a blade defined in its geometry, weight, dimensions and sharpness. The specificity of the cutting tests is such that a single cut is never expected, but a short wear cycle of the selected sample. Reporting these details of the evaluation process of a cut-resistant fabric allows us to better understand the needs and requirements of the world of sport. Confirming our attention on alpine skiing, we can well understand how the single cutting event is much more interesting and relevant than a repeated passage of a blade over the same point. A second observation to make concerns the profile of a ski edge which can never be compared directly with that of a blade and which therefore will never have the same cutting capacity. The two variables that significantly influence the characteristics of an anti-cut fabric are: the impact pressure between the edge and the fabric and the relative speed between the ski and the athlete.

The accidents

Reports of cutting injuries are now commonplace, ranging from less serious ones to those where the risk of permanent damage to the athlete comes close. It is not alarmism but a new and proven threat to our athletes: this is because it does not exclusively involve the athlete of excellence but is now a situation of real alarm even in the youth categories. In addition to the fall, we also have a case history of cuts resulting from a collision between skiers, both in open field and in Parallel Slalom competitions. We take the liberty of documenting, through images, some cases chosen from among those that demonstrate how no part of the body can be considered to be at zero risk.

- CUT RESISTANT - Tested, approved, patented safety

- Winner of the Snow Industry Award 2017

- Patented product and certified as PPE Cut Resistance Level 3 and 4 CE EN 388:2016

- Compliant with FIS CRG 2021 Test